In-Mold Labels Market Size, Trends, Segments, Share and Companies 2025-35

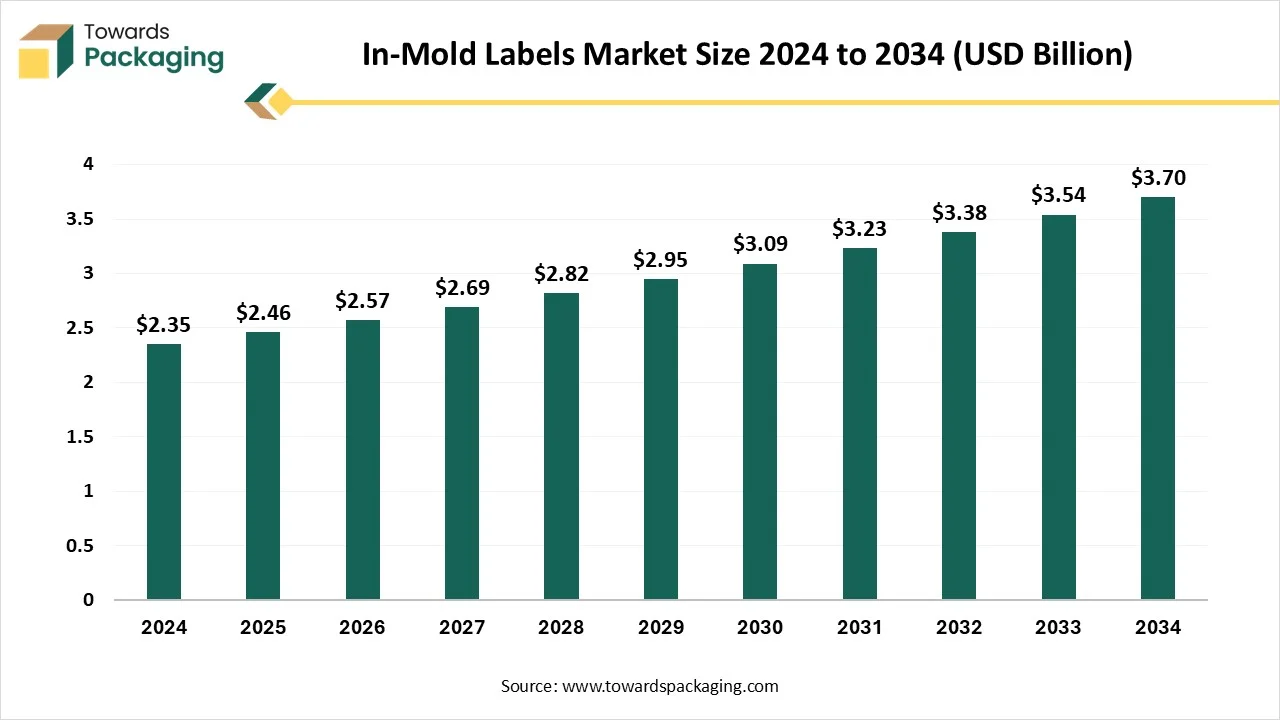

According to projections from Towards Packaging, the global in-mold labels market is set to increase from USD 2.57 billion in 2026 to nearly USD 3.70 billion by 2034, reflecting a CAGR of 4.65% during 2025 to 2034.

Ottawa, Nov. 10, 2025 (GLOBE NEWSWIRE) — The global in-mold labels market reported a value of USD 2.46 billion in 2025, and according to estimates, it will reach USD 3.70 billion by 2034, as outlined in a study from Towards Packaging, a sister firm of Precedence Research.

Request Research Report Built Around Your Goals: [email protected]

What is meant by In-mold labels?

The in-mold labels market is driven by increasing demand for visually appealing, durable, and tamper-evident packaging solutions across the food, beverage, personal care, and pharmaceutical industries. Brands are seeking innovative packaging to enhance shelf appeal, improve brand recognition, and ensure product safety, fueling the adoption of in-mold labeling technology. In-mold labels (IML) are printed labels that are integrated directly into plastic containers during the molding process, creating a single, seamless unit.

This method enhances label durability, prevents peeling or fading, and allows for high-quality, full-color designs. IML technology supports complex shapes and sustainable packaging by reducing the need for adhesives and additional labeling materials. The Asia-Pacific region leads the market due to rapid industrialization, growing consumer awareness, and expanding packaging and manufacturing sectors, while investments in advanced labeling solutions and automation further strengthen market adoption and global competitiveness.

Major Sustainability Trends in In-Mold Labels:

- Mono-materials: Using the same type of plastic for both the container and the label simplifies the recycling process and enables a true closed-loop system.

- Recycled and eco-friendly content: Incorporating post-consumer recycled (PCR) resins and sustainable inks reduces reliance on virgin materials and meets consumer demand for responsible packaging.

- Efficient, waste-reducing production processes: The single-step, automated in-mold labeling method inherently lowers energy consumption, minimizes material waste, and allows for product lightweighting compared to traditional labeling methods.

Get All the Details in Our Solutions – Access Report Sample: https://www.towardspackaging.com/download-sample/5797

What Are the Latest Key Trends in The In-Mold Labels Market?

1. Sustainable Materials

Brands are increasingly adopting biodegradable or recyclable substrates for in-mold labels, such as PLA films and mono-material solutions, to align with environmental goals and regulatory pressure.

2. Advanced Printing Technologies

Innovations like digital and 3D printing are enabling highly detailed, full-color IMLs, allowing brands to offer short runs, customization, and rapid design changes for premium packaging.

3. Automation and Efficiency in Production

Automated in-mold labeling systems are being adopted to improve accuracy, reduce waste, and increase throughput in high-speed manufacturing lines, especially in food packaging applications.

4. Integration of Smart Technologies

In-mold labels are now embedding QR codes, NFC, RFID, and augmented reality features, enabling interactive packaging, supply-chain traceability, and anti-counterfeiting capabilities.

5. Customization and Personalization

The demand for limited-edition, region-specific, or personalized packaging designs is prompting manufacturers to leverage IML for unique branding, variable data printing, and consumer-centric visual differentiation.

What is the Potential Growth Rate of the In-Mold Labels Market?

Expansion of Food & Beverage Industry & Integration of Smart Packaging

The integration of smart packaging and the expansion of the food and beverage industry are key drivers for the in-mold labels (IML) market. Smart packaging technologies, such as QR codes, NFC, and RFID-enabled labels, provide enhanced product traceability, anti-counterfeiting measures, and interactive consumer engagement, adding value to branded products.

Simultaneously, the rapid growth of the food and beverage sector, fuelled by urbanization, rising disposable incomes, and demand for packaged and convenience foods, increases the need for durable, visually appealing, and tamper-evident labeling solutions. Together, these trends accelerate the adoption of IML technology across multiple product categories.

Limitations & Challenges

Complex Manufacturing Process and Competition from Alternative Solutions

The in-mold labels market faces limitations such as high initial investment, complex manufacturing processes, and material compatibility issues. Competition from conventional labeling methods, regulatory compliance challenges, and recycling concerns further restrict adoption, particularly among small and medium-sized manufacturers.

Elevate your packaging strategy with Towards Packaging. Enhance efficiency and achieve superior results – schedule a call today: https://www.towardspackaging.com/schedule-meeting

Regional Analysis:

Who is the leader in the In-Mold Labels Market?

Asia-Pacific leads the market due to rapid industrialization, expanding food and beverage and personal care sectors, and increasing consumer demand for attractive, durable packaging. Strong manufacturing capabilities, adoption of advanced labeling technologies, and supportive government initiatives further strengthen the region’s dominance in production, innovation, and market supply chains.

What are the Ongoing Trends in the Chinese Market?

China is a leading force in the Asia-Pacific region for in-mold labels, fuelled by its massive manufacturing base and rising demand for premium packaging solutions. It benefits from strong industrial capabilities, high-volume consumer goods production, and increasing adoption of advanced labeling technologies.

What are the Latest Trends in the India Market?

India’s in-mold labels market is expanding rapidly as modern retail channels, convenience-packaged goods, and food processing sectors grow. Brands in India are using IML for enhanced shelf appeal and efficient packaging as the country industrializes and increases its packaging sophistication.

What is the opportunity for the Rise of North America in the In-Mold Labels Industry?

North America is experiencing rapid growth in the market due to increasing demand for premium, durable, and tamper-evident packaging across the food, beverage, and personal care industries. Adoption of advanced printing technologies, automated labeling systems, and smart packaging solutions enhances efficiency and product appeal. Strong focus on sustainability, regulatory compliance, and innovative marketing strategies further drives the adoption of IML across diverse manufacturing and retail sectors.

What are the Ongoing Trends in the U.S. Market?

The U.S. in-mold labels market is driven by strong demand from food & beverage and personal care sectors, where durable, full-color labels enhance brand appeal and packaging performance. Advanced printing technologies and mono-material solutions support sustainability goals and regulatory compliance, boosting adoption across manufacturers.

What are the Latest Trends in Canada

Canada’s market is expanding as food, beverage and personal care industries increase use of premium, tamper-evident labeling. Stringent environmental regulations and demand for recyclable materials encourage the shift toward in-mold labels in packaging solutions.

How Big is the Success of the Europe In-Mold Labels Market?

Europe’s in-mold labels market grows notably due to increasing demand for sustainable, tamper-evident, and visually appealing packaging across the food, beverage, and personal care industries. Advanced printing technologies, strict regulatory standards, and growing adoption of recyclable and eco-friendly labeling materials further drive market expansion and innovation in the region.

How Crucial is the Role of Latin America in the In-Mold Labels Industry?

Latin America’s in-mold labels market is growing considerably due to rising demand for attractive, durable, and tamper-evident packaging in the food, beverage, and personal care sectors. Expanding industrialization, increasing disposable incomes, and growing awareness of branding and product differentiation encourage manufacturers to adopt advanced labeling solutions across the region.

How Big is the Opportunity for the Growth of the Middle East and Africa In-Mold Labels Industry?

The Middle East and Africa present significant growth opportunities in the in-mold labels market due to increasing demand for premium, durable, and tamper-evident packaging in the food, beverage, and personal care sectors. Expanding industrialization, rising consumer awareness, and government initiatives supporting modern packaging solutions are driving the adoption of advanced labeling technologies across the region.

More Insights of Towards Packaging:

- Smart Labels Market Size, Segments, Share and Companies

- Primary Packaging Labels Market Disruptive Trends and Future Potential

- Shipping Labels Market Research, Consumer Behavior, Demand and Forecast

- Compostable Packaging Labels Market Consumer Insights & Growth Strategies

- Tamper Evident Labels Market Research, Consumer Behavior, Demand and Forecast

- Cryogenic Labels Market Outlook Scenario Planning & Strategic Insights for 2034

- Consumer Packaging Labels Market Growth, Innovations and Market Size Forecast 2034

- Food Labels Market Emerging Trends, Investment Opportunities and Competitive Benchmarking

- Biotechnology Labels and Packaging Market Research, Consumer Behavior, Demand and Forecast

- Wet Glue Labels Market Emerging Trends, Investment Opportunities and Competitive Benchmarking

- NFC-Embedded Packaging Market Dynamics 2025: Labels and Stickers Segment to Grow at Fastest CAGR

- 3D-Printed Stickers & Labels Market Size, Segments, Regional Data (NA/EU/APAC/LA/MEA) and Companies

- Self-Adhesive Labels Market 2025 Outlook

- Retail Shipping Labels Market Size, Regional Data (NA/EU/APAC/LA/MEA)

- Industrial Labels Market Size, Segmentation, Regional Outlook (NA, EU, APAC, LA, MEA)

- Shrink and Stretch Sleeve Labels Market Size, Segments Data, Regional Insight

- Pressure Sensitive Labels Market Size, Segments, Regional Data (NA/EU/APAC/LA/MEA)

Segment Outlook

Material Type Insights

What made the Polypropylene (PP) – oriented PP (OPP), biaxially oriented PP (BOPP), cast PP Segment Dominant in the In-Mold Labels Market in 2024?

The Polypropylene (PP) – oriented PP (OPP), biaxially oriented PP (BOPP), and cast PP segments dominate the market due to their excellent durability, chemical resistance, and heat stability. Its lightweight nature, cost-effectiveness, and compatibility with high-speed molding processes make it ideal for food, beverage, and personal care packaging, supporting high-quality, long-lasting, and visually appealing labeling solutions.

The polyethylene segment is the fastest-growing in the market due to its flexibility, lightweight properties, and ease of processing. Its compatibility with diverse packaging shapes, cost-effectiveness, and ability to support high-quality printing and sustainable applications drive rapid adoption across the food, beverage, and personal care industries.

Printing Insights

How the Flexography Technology Dominated the In-Mold Labels Market in 2024?

The flexography technology segment dominates the market due to its high-speed printing capabilities, cost-effectiveness, and versatility in handling various substrates. It enables vibrant, durable, and precise label designs, making it ideal for large-scale production in food, beverage, and personal care packaging applications.

The digital printing (inkjet/UV) + hybrid workflows segment is the fastest-growing in the market due to its ability to deliver high-resolution, full-color designs with rapid turnaround times. It supports customization, short production runs, and variable data printing, enabling brands to create personalized and limited-edition packaging while enhancing efficiency and reducing material waste.

End-Use Industry Insights

How did the Food & Beverages Dominated the In-Mold Labels Market in 2024?

The food & beverage segment dominates the market due to the need for durable, tamper-evident, and visually appealing packaging that enhances brand recognition. Growing demand for convenience foods, packaged beverages, and ready-to-eat products drives adoption, while IML technology ensures high-quality labeling, long shelf life, and compliance with safety and regulatory standards.

The personal care and cosmetics segment is the fastest-growing in the market due to increasing demand for premium, visually appealing, and durable packaging. IML enhances brand differentiation, supports intricate designs, and ensures tamper-evident, high-quality labeling, meeting consumer expectations for luxury and personalized cosmetic and personal care products.

Functionality Insights

What made the Standard decorative IML Segment Dominant in the In-Mold Labels Market in 2024?

The standard decorative IML segment dominates the market as it enhances product aesthetics and shelf appeal. Its ability to provide vibrant, durable, and tamper-resistant designs across food, beverage, and personal care packaging makes it the preferred choice for brands seeking consistent, high-quality decorative labeling solutions.

The RFID-enabled devices segment is the fastest-growing in the market due to increasing demand for product traceability, anti-counterfeiting measures, and supply chain efficiency. Integration of RFID technology in IML enhances inventory management, consumer engagement, and security, making it ideal for food, beverage, and high-value personal care products.

Recent Breakthroughs in In-Mold Labels Market

- In April, 2025, Tageos inaugurated its new Innovation Center of Excellence (ICoE) near Munich, backed by a multi‑million‑Euro investment with over 700 m² of R&D and project space. The facility is designed for rapid prototyping, Engineering‑as‑a‑Service (EaaS), and integration of advanced technologies such as BLE, printed antennas, flexible sensors and dual‑frequency RFID/NFC inlays tailored for in‑mold label applications. This strategic move underscores Tageos’ commitment to smart, connected IML solutions, enabling brands and converters to embed tracking, authentication and interactive features directly into molded packaging.

- On June 10, 2025, Tageos unveiled its EOS‑450 U9 inlay built on NXP’s UCODE 9 IC, approved for ARC Spec Z, specifically optimized for food supply‑chain and quick‑service‑restaurant (QSR) workflows. Key features include small form factor, high read performance on challenging substrates, and full traceability from storage to prep line. By enabling real‑time monitoring of perishable goods, expiry tracking and FIFO workflows, this innovation strengthens IML’s role in connected back‑end logistics and smart packaging for food‑service moulded containers.

- In August to October 2025, industry‑wide material innovation was highlighted by an entry recognized at the 2025 IMDA Awards: an IML film structure made from 40 % post‑consumer recycled (PCR) PE film that is fully recyclable in conventional PE streams. These developments mark a significant step: they combine high‑quality visual decoration with true circular‑economy credentials for injection‑moulded SKU packaging.

Top Companies in the Global In-Mold Labels Market

Tier 1:

- CCL Industries (incl. CCL Label): CCL Label offers a wide range of durable and cost-effective IML solutions for injection and blow molding processes, focusing on applications across food & dairy, home care, and personal care markets.

- Avery Dennison: Avery Dennison provides innovative IML solutions with an embedded RFID technology, designed to enable scalable reuse models and enhance supply chain visibility for returnable packaging assets.

- Constantia Flexibles: Constantia Flexibles sold its labels business to Multi-Color Corporation in 2017 to focus on flexible packaging, thus it no longer has a dedicated in-mold label offering.

- Coveris Holdings: Coveris offers a variety of in-mold labels as part of its broad packaging portfolio, focusing on sustainable and high-quality decorative solutions for markets including food, pet food, and industrial applications.

- Huhtamaki Group: Huhtamaki provides IML solutions, primarily utilizing flexography and gravure printing technologies for both injection and blow molding, used widely in the food, dairy, and chemical industries.

- Multi-Color Corporation (MCC / Multi-Color): MCC, through its acquisition of Constantia’s labels business and its IML specialist Verstraete, offers extensive IML options known for maximum print quality, durability, and a sustainable mono-material approach for full recyclability.

- Fuji Seal International: Fuji Seal specializes in various labeling technologies, including pressure-sensitive and shrink sleeve labels, and focuses on eco-friendly material usage and resource circulation in its offerings.

- Jindal Films: Jindal Films manufactures the specialized BOPP and BOPE films (under the LABEL-LYTE and Ethy-Lyte brands) that are used by converters and printers to produce the actual in-mold labels, rather than producing the final labels themselves.

Tier 2:

- Innovia Films (and other specialty film makers).

- Inland Label & Marketing Services / Inland Packaging.

- EVCO Plastics (converter & molder with IML capability).

- Cosmo Films.

- Taghleef Industries (film supplier).

- Mold-Tek Packaging (India) / Mold-Tek Group.

- Letra Graphix / ORIANA Décorpack / regional specialized converters (grouped representative).

Global In-Mold Labels Market Segments

By Material / Film

- Polypropylene (PP) – oriented PP (OPP), biaxially oriented PP (BOPP), cast PP

- Polyethylene (PE) – HDPE, LDPE

- Polystyrene (PS) / OPS

- PET (polyethylene terephthalate)

- PVC (polyvinyl chloride)

- ABS & specialty resins

By Printing/Converting Technology

- Flexographic printing

- Offset (lithographic) printing

- Rotogravure (gravure) printing

- Digital printing (inkjet/UV) + hybrid workflows

- Secondary converting: metallization, varnishing, laminating, die-cutting

By End-Use Industry/Application

- Food & beverage (cups, tubs, trays, yogurt pots)

- Dairy (yogurt cups, cheese tubs)

- Home care & household chemicals

- Personal care & cosmetics

- Pharmaceutical & healthcare

- Automotive (interior trims, durable parts)

- Consumer electronics & appliances

- Industrial/technical parts (pails, buckets, crates)

By Functionality/Value-Add

- Standard decorative IML

- Functional IML: RFID-enabled / NFC / anti-counterfeit / tamper-evident

- Barrier/specialty coatings (UV, chemical resistance)

By Region

North America:

- U.S.

- Canada

- Mexico

- Rest of North America

South America:

- Brazil

- Argentina

- Rest of South America

Europe

Western Europe

- Germany

- Italy

- France

- Netherlands

- Spain

- Portugal

- Belgium

- Ireland

- UK

- Iceland

- Switzerland

- Poland

- Rest of Western Europe

Eastern Europe

- Austria

- Russia & Belarus

- Türkiye

- Albania

- Rest of Eastern Europe

Asia Pacific:

- China

- Taiwan

- India

- Japan

- Australia and New Zealand,

- ASEAN Countries (Singapore, Malaysia)

- South Korea

- Rest of APAC

MEA:

- GCC Countries

- Saudi Arabia

- United Arab Emirates (UAE)

- Qatar

- Kuwait

- Oman

- Bahrain

- South Africa

- Egypt

- Rest of MEA

Invest in Our Premium Strategic Solution: https://www.towardspackaging.com/checkout/5797

Request Research Report Built Around Your Goals: [email protected]

About Us

Towards Packaging is a global consulting and market intelligence firm specializing in strategic research across key packaging segments including sustainable, flexible, smart, biodegradable, and recycled packaging. We empower businesses with actionable insights, trend analysis, and data-driven strategies. Our experienced consultants use advanced research methodologies to help companies of all sizes navigate market shifts, identify growth opportunities, and stay competitive in the global packaging industry.

Stay Connected with Towards Packaging:

- Find us on Social Platforms: LinkedIn | Twitter | Instagram

- Subscribe to Our Newsletter: Towards Sustainable Packaging

- Visit Towards Packaging for In-depth Market Insights: Towards Packaging

- Read Our Printed Chronicle: Packaging Web Wire

- Get ahead of the trends – follow us for exclusive insights and industry updates:

Pinterest | Medium | Tumblr | Hashnode | Bloglovin | LinkedIn – Packaging Web Wire - Contact: APAC: +91 9356 9282 04 | Europe: +44 778 256 0738 | North America: +1 8044 4193 44

Our Trusted Data Partners

Precedence Research | Statifacts | Towards Healthcare | Towards Auto | Towards Food and Beverages | Towards Chemical and Materials | Towards Consumer Goods | Towards Dental | Towards EV Solutions | Nova One Advisor | Healthcare Webwire | Packaging Webwire | Automotive Webwire | Nutraceuticals Func Foods | Onco Quant | Sustainability Quant | Specialty Chemicals Analytics

Towards Packaging Releases Its Latest Insight – Check It Out:

- PTFE Tapes and Films Market Size, Segments, Companies, Competitive Analysis

- Rice Paper Packaging Market Growth, Key Segments, and Regional Dynamics

- Sauces, Dressings and Condiments Packaging Market Size, Trends, Share

- Tetrahedron Carton Market Size, Trends, Share, Trends, Segments

- Semiconductor Assembly Packaging Equipment Market Growth

- Release Liners Market Market Size, Trends, Share, Trends, Segments

- High-Barrier Materials for Pharmaceutical Packaging Market Size

- Mono-oriented Polypropylene (MOPP) Films Market Size, Trends, Share

- Plastic Dielectric Films Market Size, Trends, Key Segments, and Regional Dynamic

- Monodose Packaging For Probiotic and Nutraceutical Market Size

- Suppository Packaging Market Size, Trends, Share, Trends, Segments

- Sealed Wax Packaging Market Size, Trends, Share, Trends, Segments

- Packaging Nets Market Size, Segments, Companies, Competitive Analysis

- Cell Therapy Packaging Market Size, Trends, Segments, Companies

- Halal Packaging Market Size, Trends, Segments, Companies, Competitive Analysis

Disclaimer: The above press release comes to you under an arrangement with GlobeNewswire. DailyIndiaNews.com takes no editorial responsibility for the same.

Disclaimer: The above press release comes to you under an arrangement with GlobeNewswire. DailyIndiaNews.com takes no editorial responsibility for the same.